แนวทางปฏิบัติที่ยั่งยืนในการผลิตชิ้นส่วนรถยนต์สำหรับอุบัติเหตุ

การเปลี่ยนผ่านสู่การผลิตที่ยั่งยืนและเป็นมิตรกับสิ่งแวดล้อมในภาคอุตสาหกรรมยานยนต์

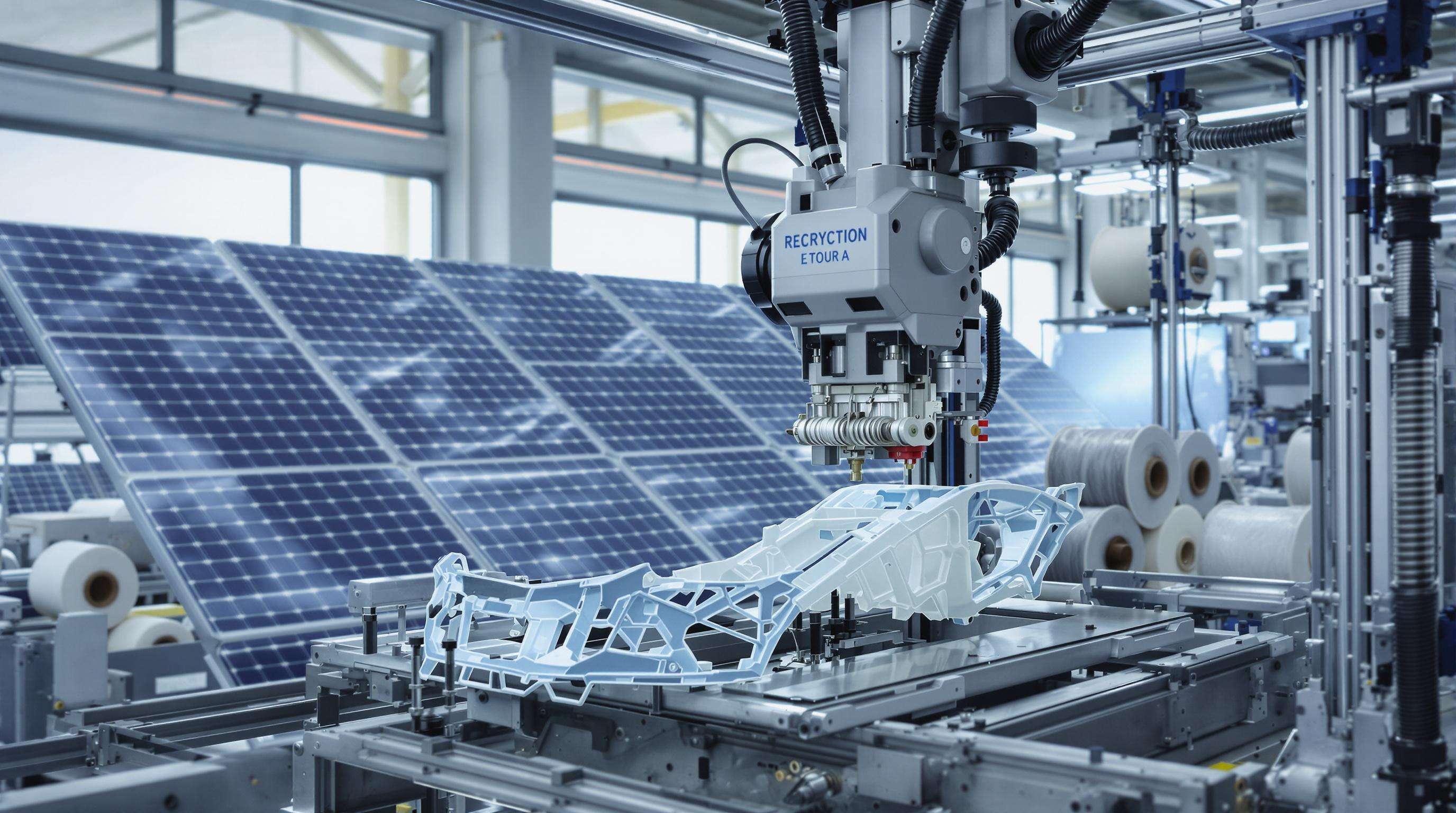

บริษัทผู้ผลิตชิ้นส่วนอะไหล่รถยนต์ชนิดต่างๆ กำลังหันมาให้ความสำคัญกับแนวทางการผลิตที่เป็นมิตรต่อสิ่งแวดล้อมมากขึ้น เพื่อให้บรรลุเป้าหมายด้านสภาพภูมิอากาศของโลก บริษัทชั้นนำในอุตสาหกรรมนี้ได้เริ่มใช้พลังงานแสงอาทิตย์และนำวัสดุเก่ามาใช้ซ้ำใหม่ แทนที่จะพึ่งพาแต่วัสดุใหม่ที่ผลิตขึ้นจากพื้นฐานเดิม โดยจากการวิจัยที่ทำไว้เมื่อปีที่แล้ว พบว่า การผลิตชิ้นส่วนโดยใช้วิธีการที่เป็นมิตรต่อสิ่งแวดล้อมนั้นสามารถลดการปล่อยคาร์บอนได้ประมาณ 34 เปอร์เซ็นต์ เมื่อเทียบกับวิธีการผลิตแบบดั้งเดิม นอกจากนี้ยังมีข้อมูลจากมูลนิธิเอลเลน แมคอาเธอร์ (Ellen MacArthur Foundation) ที่ระบุว่าแนวคิดเศรษฐกิจหมุนเวียน (Circular Economy) อาจช่วยลดการปล่อยก๊าซเรือนกระจกในอุตสาหกรรมรถยนต์โดยรวมได้ถึงเกือบครึ่งหนึ่งภายในระยะเวลาเพียง 7 ปี หากเรามีการนำวัสดุมาใช้ซ้ำอย่างมีประสิทธิภาพมากขึ้น พร้อมทั้งออกแบบระบบการผลิตใหม่โดยรวม

หลักการพื้นฐานของการผลิตที่ยั่งยืนในอุตสาหกรรมชิ้นส่วนรถยนต์

หลักการพื้นฐานสามข้อที่กำหนดแนวทางการผลิตที่เป็นมิตรต่อสิ่งแวดล้อม:

- ประสิทธิภาพในการใช้ทรัพยากร : การเพิ่มประสิทธิภาพการใช้น้ำและพลังงานผ่านเทคโนโลยีการขึ้นรูปขั้นสูง

- การลดขยะ : การใช้ระบบการรีไซเคิลแบบวงจรปิดสำหรับโลหะและโพลิเมอร์

- การออกแบบตลอดวงจรชีวิต : การออกแบบชิ้นส่วนต่างๆ เช่น กันชนและฝากระโปรงให้ถอดแยกและนำกลับมาใช้ใหม่ได้ง่าย

กลยุทธ์เหล่านี้ช่วยให้ผู้ผลิตลดขยะวัสดุได้ 18–22% ตามรายงานการผลิตปี 2024

การบูรณาการข้อบังคับด้านสิ่งแวดล้อมและความยั่งยืนในการผลิยานยนต์

มาตรฐานการปล่อยมลพิษที่เข้มงวด เช่น มาตรฐาน Euro 7 (2025) และข้อบังคับ CAFE กำลังเร่งการนำแนวทางการผลิตที่ยั่งยืนมาใช้ การตรวจสอบด้านสิ่งแวดล้อมปัจจุบันเป็นสิ่งบังคับแล้ว โดยมีผู้จัดจำหน่ายชิ้นส่วนสำหรับซ่อมชนิดต่างๆ 78% รายงานว่ามีความสอดคล้องกับข้อบังคับที่ดีขึ้นตั้งแต่ปี 2022 เป็นต้นมา การสอดคล้องกับข้อบังคับนี้ช่วยให้แน่ใจว่าชิ้นส่วนต่างๆ จะตรงตามทั้งมาตรฐานความปลอดภัยและความยั่งยืน พร้อมเสริมสร้างความทนทานและการนำกลับมาใช้ซ้ำได้ตลอดห่วงโซ่อุปทาน

การวัดผลการลดผลกระทบต่อสิ่งแวดล้อมในการผลิยานยนต์

การประเมินตลอดวงจรชีวิต (LCAs) ใช้วัดความก้าวหน้าด้านความยั่งยืนโดยใช้ตัวชี้วัดประสิทธิภาพหลัก (KPIs):

| เมตริก | เป้าหมายปรับปรุง (2025) | ค่าเฉลี่ยอุตสาหกรรมปัจจุบัน |

|---|---|---|

| การใช้พลังงาน | ลดลง 30% | ลดลง 17% (2023) |

| การใช้วัสดุที่ผ่านการรีไซเคิล | การดำเนินการ 45% | การดำเนินการ 32% |

ระบบติดตามอัตโนมัติช่วยให้สามารถตรวจสอบข้อมูลเหล่านี้แบบเรียลไทม์ในสิ่งอำนวยความสะดวกด้านอะไหล่ชนตัวถังรุ่นใหม่ 92% ช่วยเพิ่มความรับผิดชอบและความโปร่งใสในการดำเนินงาน

การสร้างสมดุลระหว่างประสิทธิภาพด้านต้นทุนกับการผลิตที่ยั่งยืนในอุตสาหกรรมอะไหล่ชนตัวถัง

เทคโนโลยีการกู้คืนวัสดุขั้นสูงช่วยลดต้นทุนการผลิตอย่างยั่งยืนลง 28% ตั้งแต่ปี 2021 การศึกษาของ McKinsey ในปี 2023 พบว่าผู้ผลิตที่รวมเทคนิค Lean เข้ากับแนวทางเศรษฐกิจหมุนเวียน (Circular) สามารถเพิ่มอัตรากำไรจากการผลิตอะไหล่ชนตัวถังได้สูงขึ้น 19% ขณะที่ยังคงความสอดคล้องตามข้อกำหนด ความได้เปรียบทางเศรษฐกิจนี้กำลังขับเคลื่อนการนำระบบดังกล่าวไปใช้อย่างแพร่หลาย โดยผู้จัดหา 64% ปัจจุบันกำลังทดลองใช้สายการผลิตที่ไม่สร้างขยะ (Zero-waste)

การรีไซเคิล การนำกลับมาใช้ใหม่ และเศรษฐกิจหมุนเวียนในกระบวนการผลิตอะไหล่ชนตัวถัง

บทบาทของวัสดุที่ผ่านการรีไซเคิลในกระบวนการผลิตรถยนต์และการทนทานของอะไหล่ชนตัวถัง

ชิ้นส่วนรถยนต์ในปัจจุบันเริ่มมีการนำวัสดุรีไซเคิลมาใช้มากขึ้น เช่น โพลิเมอร์และโลหะผสมอลูมิเนียม ซึ่งวัสดุเหล่านี้สามารถใช้งานได้ดีเท่ากับวัสดุใหม่ในกรณีที่เกิดการชนกัน ยกตัวอย่างเช่น กันชน – ในแกนหลักมีส่วนผสมของโพลีโพรพิลีนรีไซเคิลประมาณ 35 ถึง 40 เปอร์เซ็นต์ และยังสามารถผ่านการทดสอบความทนทานตามมาตรฐาน ISO 17373 ที่เข้มงวดได้ นอกจากนี้ข้อมูลตลอดวงจรชีวิตผลิตภัณฑ์จากรายงานผลกระทบด้านวัสดุปี 2023 ยังแสดงให้เห็นอีกอย่างหนึ่งที่น่าสนใจด้วย นั่นคือฝากระโปรงที่ผลิตจากวัสดุรีไซเคิลมีผลกระทบต่อปริมาณคาร์บอนน้อยลงประมาณ 28% เมื่อเทียบกับแบบปกติ อุตสาหกรรมยานยนต์กำลังลดการพึ่งพาพลาสติกที่ทำจากน้ำมัน ซึ่งช่วยอนุรักษ์ทรัพยากรในระยะยาว ผู้ผลิตรถยนต์พบว่า การพัฒนาอย่างยั่งยืนนั้นไม่จำเป็นต้องแลกมาด้วยการลดคุณภาพหรือความปลอดภัย

ความก้าวหน้าในการนำวัสดุกลับมาใช้ใหม่และรีไซเคิลสำหรับระบบกันชนและแฟลร์ล้อ

การดีโพลีเมอไรเซชันทางเคมีช่วยให้กู้คืนวัสดุได้ถึง 95% จากกันชนที่หมดอายุการใช้งาน ซึ่งสูงกว่าผลผลิตที่ได้จากการรีไซเคิลเชิงกลที่ 60% อย่างมาก ในกระบวนการผลิตแผงกันโคลง ความก้าวหน้าในการทำให้โลหะผสมมีความสม่ำเสมอช่วยให้สามารถใช้เศษอลูมิเนียมจากผู้บริโภคหลังการใช้งานได้ในสัดส่วน 30–50% ซึ่งมีความต้านทานต่อการบุบได้เทียบเท่าวัสดุใหม่ พร้อมลดการใช้พลังงานลง 44% (ริเริ่มความยั่งยืนอลูมิเนียม 2024)

กรณีศึกษา: การรีไซเคิลแบบวงจรปิดในสายการผลิตของผู้จัดหาชั้นนำระดับ Tier-1

การศึกษาเกี่ยวกับความยั่งยืนของเหล็กในปี 2024 แสดงให้เห็นว่าการผลิตชิ้นส่วนโครงรถใหม่ช่วยลดการใช้เหล็กใหม่ลงได้ถึง 62% ในโรงงานระดับ Tier-1 โดยการนำระบบคัดแยกด้วยเลเซอร์และเตาลดแบบตรงมาใช้ ซึ่งช่วยลดการปล่อยก๊าซเรือนกระจกตลอดวงจรชีวิตลง 40% ต่อตันของเหล็กเกรดชนิดพิเศษสำหรับการชน โดยยังคงไว้ซึ่งการปฏิบัติตามมาตรฐาน IATF 16949—พิสูจน์ให้เห็นว่าประสิทธิภาพสูงและความยั่งยืนสามารถอยู่ร่วมกันได้

การออกแบบเพื่อการถอดแยกและผลิตใหม่ของชิ้นส่วนรถยนต์ที่เกี่ยวข้องกับการชน

ผู้ผลิตรถยนต์กำลังออกแบบกันชนและแผงข้างรถโดยใช้ชิ้นส่วนยึดมาตรฐาน และผลิตจากวัสดุเดียว ซึ่งช่วยให้การถอดชิ้นส่วนออกใช้เวลารวดเร็วขึ้นประมาณ 80% เมื่อพูดถึงฝากระโปรงหน้า พวกเขากำลังทดลองใช้ระบบล็อกแบบ snap fit และการยึดติดที่ไม่ต้องใช้กาว วิธีการใหม่เหล่านี้แสดงให้เห็นว่าสามารถกู้คืนชิ้นส่วนได้ประมาณ 90% ในการทดสอบ ซึ่งดีกว่าการออกแบบแบบเดิมมาก ที่มีเพียงแค่ประมาณครึ่งเดียวที่ถอดออกมาอย่างสมบูรณ์ นอกจากนี้ยังเป็นช่วงเวลาที่เหมาะสมมากด้วย เนื่องจากส่วนใหญ่แล้วการซ่อมแซมรถยนต์เกิดขึ้นในช่วงต้นของอายุการใช้งาน ตามรายงานดัชนีความยั่งยืนของอุตสาหกรรมยานยนต์ปี 2024 ระบุว่า โดยประมาณ 7 จากทุก 10 ครั้งของการเปลี่ยนชิ้นส่วนจากอุบัติเหตุเกิดขึ้นภายในระยะเวลาเพียงแค่ 8 ปีหลังจากที่รถยนต์คันนั้นออกจากโชว์รูม

วัสดุนวัตกรรม: วัสดุรีไซเคิลและวัสดุน้ำหนักเบาเพื่อความยั่งยืน

ประโยชน์ของการผสมผสานวัสดุรีไซเคิลเข้ากับการออกแบบน้ำหนักเบา

ผู้ผลิตรถยนต์ที่ลดการปล่อยก๊าซเรือนกระจก ได้เห็นการลดลงระหว่าง 18 ถึง 24 เปอร์เซ็นต์ เมื่อพวกเขาผสมวัสดุรีไซเคิลเข้ากับการออกแบบชิ้นส่วนชนิดเบาสำหรับใช้ในระบบความปลอดภัย แนวทางสองประการนี้ช่วยลดการใช้พลังงานในโรงงานลงได้ประมาณ 35 เปอร์เซ็นต์ เมื่อเทียบกับวิธีการผลิตแบบดั้งเดิม โดยไม่กระทบต่ำมาตรฐานความปลอดภัย ยกตัวอย่างเช่น ชิ้นส่วนฝากระโปรงหน้า หลายผู้ผลิตรถยนต์ปัจจุบันได้ออกแบบชิ้นส่วนเหล่านี้ใหม่ ทำให้ใช้วัสดุโลหะเศษเหลือเพียงประมาณ 40 เปอร์เซ็นต์ในกระบวนการตัดพัมพ์ (stamping) ซึ่งแน่นอนว่าหมายถึงวัสดุที่เหลือทิ้งไว้ในหลุมฝังกลบขยะของประเทศจะลดน้อยลง

นวัตกรรมวัสดุ: โพลิเมอร์รีไซเคิลและโลหะผสมอลูมิเนียมในกันชนและฝากระโปรง

แกนกันชนในปัจจุบันมีสัดส่วนประมาณ 30 ถึง 50 เปอร์เซ็นต์ที่ทำมาจากพอลิเมอร์รีไซเคิล โดยมักจะผสมเข้ากับโลหะผสมอลูมิเนียมที่มีสัดส่วนเศษเหลือใช้หลังกระบวนการอุตสาหกรรมประมาณ 70 เปอร์เซ็นต์ การศึกษาล่าสุดในปี 2023 แสดงให้เห็นว่าการใช้วัสดุผสมชนิดนี้สามารถลดการปล่อยก๊าซคาร์บอนได้เกือบ 60 เปอร์เซ็นต์ เมื่อเทียบกับการใช้วัสดุใหม่ทั้งหมด และยังสามารถผ่านการทดสอบความทนทานตามมาตรฐานที่ผู้ผลิตรถยนต์กำหนดได้อีกด้วย อลูมิเนียมมีความโดดเด่นตรงที่สามารถนำกลับมาใช้ซ้ำได้ไม่จำกัดโดยไม่เสียคุณภาพมากนัก ยังคงคุณสมบัติไว้ได้ประมาณ 95 เปอร์เซ็นต์ แม้จะผ่านการใช้งานซ้ำหลายรอบ ซึ่งทำให้อลูมิเนียมเป็นตัวเลือกที่เหมาะสมเป็นพิเศษสำหรับชิ้นส่วนอย่างกันชนข้างและแผ่นข้างรถ ที่ต้องคำนึงถึงทั้งความแข็งแรงและผลกระทบต่อสิ่งแวดล้อม

การทดสอบสมรรถนะของวัสดุที่ยั่งยืนภายใต้การจำลองการชน

การตรวจสอบจากบุคคลที่สามยังคงมีความสำคัญต่อการยอมรับในตลาด ผลการทดสอบเทียบเท่า NCAP ล่าสุดแสดงให้เห็นว่า

| การจับคู่วัสดุ | การดูดซับพลังงาน | การลดน้ำหนัก |

|---|---|---|

| พอลิโพรพิลีนรีไซเคิล + อลูมิเนียม | ปรับปรุงขึ้น 12% | เบากว่า 22% |

| คอมโพสิตชีวภาพ + เหล็ก | ปรับปรุงขึ้น 7% | เบากว่า 15% |

ผลลัพธ์เหล่านี้ยืนยันว่าวัสดุที่ยั่งยืนไม่เพียงแต่เป็นไปตามมาตรฐานความปลอดภัย แต่ยังสามารถเกินกว่ามาตรฐานดังกล่าว ซึ่งสนับสนุนการนำวัสดุเหล่านี้เข้าสู่ระบบนิเวศการซ่อมแซมหลังการชน

เทคโนโลยีการผลิตขั้นสูงที่ขับเคลื่อนความยั่งยืน

การพิมพ์แบบสามมิติเปลี่ยนแปลงวิธีการผลิตที่ยั่งยืนอย่างไร

การศึกษาในปี 2023 แสดงให้เห็นว่าการพิมพ์ 3 มิติช่วยลดของเสียจากวัสดุที่ใช้ในการผลิตชิ้นส่วนรถยนต์ โดยบางครั้งสามารถลดได้มากถึง 90% เมื่อเทียบกับวิธีการตัดแบบดั้งเดิม เทคโนโลยีนี้ทำให้สามารถผลิตชิ้นส่วนที่มีความซับซ้อนได้ เช่น ชิ้นส่วนที่ยึดกันชนและชิ้นส่วนรองรับแฟริ่งที่มีรูปทรงซับซ้อน โดยไม่สิ้นเปลืองวัตถุดิบมากนัก เนื่องจากทุกอย่างถูกสร้างขึ้นตามขนาดที่ต้องการพอดี แต่ก็มีข้อเสียที่ควรกล่าวถึงเช่นกัน เครื่องพิมพ์ 3 มิติที่ใช้ในระดับอุตสาหกรรมนั้นใช้ไฟฟ้ามากกว่าเครื่องจักรกดโลหะแบบทั่วไปถึง 60% ต่อการผลิตหนึ่งชิ้น อย่างไรก็ตาม หลายบริษัทกำลังพยายามแก้ไขปัญหานี้ ตัวอย่างเช่น ผู้ผลิตรายใหญ่เพิ่งสามารถลดปริมาณคาร์บอนฟุตพรินต์โดยรวมได้ประมาณ 22% หลังจากติดตั้งระบบผลิตไฟฟ้าพลังงานแสงอาทิตย์ร่วมกับการใช้วัสดุรีไซเคิลในกระบวนการพิมพ์

Digital Twins และการปรับปรุงประสิทธิภาพด้วย AI ในการผลิตที่เป็นมิตรต่อสิ่งแวดล้อม

จากรายงานล่าสุดของ Forbes Technology Council เกี่ยวกับแนวทางการผลิตที่ยั่งยืนในปี 2024 บริษัทที่นำระบบการบำรุงรักษาเชิงพยากรณ์ที่ขับเคลื่อนด้วย AI มาใช้ ได้เห็นการลดลงของพลังงานที่ใช้ในการดำเนินการตัดหรือกดขึ้นรูป (stamping operations) ประมาณ 30 เปอร์เซ็นต์ เมื่อผู้ผลิตสร้างแบบจำลองดิจิทัลของสายการผลิตของตนเองขึ้น พวกเขาจะสามารถควบคุมการเคลื่อนที่ของวัสดุภายในระบบได้ดีขึ้น ส่งผลให้ระดับของเสียลดลงอย่างมาก บางครั้งสามารถลดอัตราของเศษวัสดุเหลือทิ้งได้ถึง 40% สิ่งที่น่าสนใจคือ แบบจำลองเสมือนเหล่านี้สามารถทดสอบได้จริงว่าฝากระโปรงหน้ารถยนต์ที่ทำจากอลูมิเนียมรีไซเคิลสามารถต้านทานการกัดกร่อนได้ดีเพียงใด ซึ่งหมายความว่าวิศวกรไม่จำเป็นต้องสร้างต้นแบบทางกายภาพที่มีค่าใช้จ่ายสูงขึ้น เมื่อพัฒนาผลิตภัณฑ์ใหม่ ทำให้กระบวนการวิจัยและพัฒนาเร็วขึ้นอย่างมาก

การวิเคราะห์แนวโน้ม: การนำเทคโนโลยีการผลิตขั้นสูงไปใช้โดยผู้ผลิตอุปกรณ์เดิม (OEMs)

มากกว่า 75% ของผู้ผลิตอุตสาหกรรมยานยนต์รายใหญ่กำลังทดลองใช้ระบบการพิมพ์ 3 มิติ หรือระบบดิจิทัลทวินสำหรับกระบวนการทำงานของชิ้นส่วนที่เกิดการชนกัน โดยมีเป้าหมายในการสอดคล้องกับวัตถุประสงค์ด้านความยั่งยืนควบคู่ไปกับต้นทุนและประสิทธิภาพ ความเร็วในการนำระบบเหล่านี้มาใช้นั้นสูงกว่าถึง 2.3 เท่าในภูมิภาคที่มีข้อกำหนดด้านการปล่อยมลพิษที่เข้มงวด ซึ่งแสดงให้เห็นถึงอิทธิพลของนโยบายที่ชัดเจน ผู้ที่นำระบบเหล่านี้มาใช้ในระยะเริ่มต้นรายงานว่าสามารถนำชิ้นส่วนแผงที่ได้รับการรับรองด้านสิ่งแวดล้อมออกสู่ตลาดได้เร็วขึ้นถึง 18%

การวิเคราะห์ข้อถกเถียง: การบริโภคพลังงานเทียบกับการประหยัดวัสดุในการพิมพ์ 3 มิติ

| สาเหตุ | การพิมพ์สามมิติ | การผลิตแบบดั้งเดิม |

|---|---|---|

| ประสิทธิภาพทางวัสดุ | ลดของเสียได้ถึง 90% | สูญเสียวัสดุ 35–50% |

| การใช้พลังงาน | สูงกว่าต่อหน่วย 60% | การใช้งานพื้นฐานต่ำกว่า |

| ความสามารถในการรีไซเคิล | การกู้คืนแบบวงจรปิด 85% | ค่าเฉลี่ยอุตสาหกรรม 72% |

แม้ว่าการพิมพ์ 3 มิติจะมีความโดดเด่นในแง่ของการลดของเสีย แต่ความต้องการพลังงานที่สูงกว่านั้นจำเป็นต้องมีการจัดการอย่างมีกลยุทธ์ แนวทางแบบผสมผสาน เช่น การใช้เครื่องพิมพ์ที่ใช้พลังงานหมุนเวียนร่วมกับวัสดุที่นำกลับมาใช้ใหม่ ได้แสดงให้เห็นถึงประสิทธิภาพในการลดผลกระทบต่อสิ่งแวดล้อมโดยรวม

การรับมือกับความท้าทายด้านซัพพลายเชนและต้นทุนในชิ้นส่วนรถยนต์ที่ยั่งยืน

ผลกระทบของต้นทุนวัตถุดิบต่อความสามารถในการขยายการผลิตอย่างยั่งยืน

จากรายงานอุตสาหกรรมล่าสุดในปี 2023 พบว่าผู้จัดจำหน่ายประมาณสามในสี่มองว่าวัสดุที่ยั่งยืนมีราคาสูงกว่าทางเลือกทั่วไปราว 32 ถึง 45 เปอร์เซ็นต์ ซึ่งแน่นอนว่าสร้างปัญหาให้กับธุรกิจจำนวนมาก ตัวอย่างเช่น อลูมิเนียมรีไซเคิลที่ใช้ในชิ้นส่วนรถยนต์ เช่น ฝากระโปรงและกันชน มีราคาประมาณ 3,800 ดอลลาร์สหรัฐต่อตัน ซึ่งสูงกว่าวัสดุใหม่ราว 15 ดอลลาร์สหรัฐ นอกจากนี้ยังมีกันชนคอมโพสิตโพลีเมอร์ที่ทำจากวัสดุรีไซเคิล ซึ่งทำให้ต้นทุนการผลิตเพิ่มขึ้นระหว่าง 7 ถึง 12 เปอร์เซ็นต์ สำหรับบริษัทที่มีกำไรขั้นต้นเพียง 6 ถึง 8 เปอร์เซ็นต์ การเพิ่มขึ้นของต้นทุนเหล่านี้ย่อมส่งผลกระทบต่อผลประกอบการโดยตรง สถาบันโพนีมอนได้ศึกษาประเด็นดังกล่าวในปี 2023 และยืนยันสิ่งที่ผู้เชี่ยวชาญในอุตสาหกรรมหลายคนทราบดีอยู่แล้ว

การสร้างซัพพลายเชนที่แข็งแกร่งสำหรับวัสดุรีไซเคิลและวัสดุที่ยั่งยืน

เพื่อให้มั่นใจถึงการไหลเวียนของวัสดุที่ยั่งยืน ผู้ผลิตชั้นนำต่างนำแนวทางหลักสามประการมาใช้

- เครือข่ายการจัดหาจากหลายแหล่ง : 58% ของซัพพลายเออร์ระดับ 1 ปัจจุบันทำงานร่วมกับผู้ให้วัสดุรีไซเคิลสามรายหรือมากกว่าต่อชิ้นส่วนหนึ่งชิ้น

- การยืนยันด้วยบล็อกเชน : ลดปัญหาความขัดแย้งด้านคุณภาพลง 42% ด้วยการติดตามตรวจสอบแบบโปร่งใสตลอดกระบวนการ

- ศูนย์กลางวัสดุระดับภูมิภาค : ศูนย์รีไซเคิลในท้องถิ่นช่วยลดการปล่อยก๊าซจากการขนส่งลง 37% (รายงานริเริ่มสิ่งใหม่ของวัสดุ 2024)

รายงานของ MDPI ปี 2024 เกี่ยวกับความยืดหยุ่นของห่วงโซ่อุปทานได้เน้นย้ำถึงการที่แพลตฟอร์มจัดซื้อที่ขับเคลื่อนด้วย AI ช่วยลดระยะเวลาการจัดหาวัสดุที่ยั่งยืนลง 19 วัน ในขณะที่แบบจำลองการทดสอบวัสดุเชิงทำนายช่วยแก้ปัญหาคุณภาพที่ไม่สม่ำเสมอ—ลดต้นทุนการควบคุมคุณภาพลง 28% และเพิ่มความน่าเชื่อถือทั่วทั้งเครือข่าย

ส่วน FAQ

หลักการพื้นฐานของการผลิตที่ยั่งยืนสำหรับชิ้นส่วนรถยนต์ที่ชนคืออะไร?

หลักการพื้นฐานรวมถึงประสิทธิภาพในการใช้ทรัพยากร การลดขยะ และการออกแบบตามวงจรชีวิต

ข้อบังคับด้านสิ่งแวดล้อมมีอิทธิพลต่ออุตสาหกรรมการผลิตยานยนต์อย่างไร?

ข้อบังคับด้านสิ่งแวดล้อม เช่น มาตรฐาน Euro 7 และ CAFE กำลังส่งเสริมแนวทางปฏิบัติที่ยั่งยืน โดยการรับรองความสอดคล้องตามเกณฑ์ความปลอดภัยและเกณฑ์ด้านความยั่งยืน

การพิมพ์แบบ 3 มิติช่วยสนับสนุนการผลิตที่ยั่งยืนอย่างไร

การพิมพ์แบบ 3 มิติสามารถลดของเสียจากวัสดุได้ถึง 90% และช่วยให้ผลิตชิ้นส่วนที่ซับซ้อนได้ง่ายขึ้น โดยใช้วัสดุดิบลดลง แม้กระนั้นยังต้องใช้พลังงานต่อหน่วยมากกว่า

วัสดุรีไซเคิลมีบทบาทอย่างไรในชิ้นส่วนรถยนต์ที่ใช้ในกรณีการชน

วัสดุรีไซเคิลอย่างเช่น โพลิเมอร์และโลหะผสมอลูมิเนียม ถูกนำไปใช้ในชิ้นส่วนต่างๆ เช่น กันชนและฝากระโปรง เพื่อรักษาสมรรถนะ ขณะเดียวกันก็ช่วยลดการปล่อยก๊าซคาร์บอนและอนุรักษ์ทรัพยากร

อุปสรรคในการขยายการผลิตชิ้นส่วนสำหรับการชนที่ยั่งยืนมีอะไรบ้าง

อุปสรรคที่พบ ได้แก่ ต้นทุนที่สูงขึ้นของวัสดุที่ยั่งยืน และความจำเป็นในการสร้างห่วงโซ่อุปทานที่แข็งแกร่ง เพื่อสนับสนุนการไหลเวียนของวัสดุและการควบคุมคุณภาพ