The Role of Quality Car Lamp Assemblies in Automotive Safety Standards

Global Safety Standards and Regulatory Frameworks for Car Lamp Assemblies

Overview of DOT, ECE, and UKCA Certification Standards for Headlights

Car lights need to pass certain certification tests before they can hit the roads safely. Over in America, the DOT requires all vehicles to follow FMVSS 108 rules. These rules basically set how bright headlights should be, somewhere between 500 to 3,000 candela, and also define what shape the light beams should take. Across the pond in Europe, their ECE regulations focus more on reducing glare for other drivers. They cap headlight brightness at around 140,000 candela and actually demand that cars have those fancy adaptive beam features now. After Brexit happened, the UK created its own standards called UKCA. While these are pretty similar to the European ones, there's extra testing required specifically for bad weather conditions since Britain gets so much rain and fog.

Key Differences Between FMVSS 108 and ECE Regulations for Automotive Lighting

While both standards aim to reduce accidents, FMVSS 108 and ECE regulations differ significantly:

| Metric | FMVSS 108 (US) | ECE (Europe) |

|---|---|---|

| Brightness Limit | 1,200 cd/m² (low beam) | 75,000 cd (total output) |

| Beam Adjustment | Fixed vertical alignment | Dynamic leveling required |

| Color Temperature | ≈ 6,500K | ≈ 6,000K |

These variations require manufacturers to redesign lamp assemblies for regional markets, increasing production costs by 12–18% (Ponemon 2023).

Regional Compliance Requirements: US, Europe, and Asia

- US: DOT certification is mandatory for all OEM and aftermarket headlights, with NHTSA conducting random audits.

- Europe: ECE R48 and R112 require adaptive lighting for vehicles exceeding 30 mph.

- Asia: China’s GB 25991-2010 combines ECE glare limits with DOT-style intensity metrics, while Japan’s JIS D 5500 mandates amber turn signals.

Non-compliant imports face rejection rates of 23% in EU customs and 17% at U.S. ports (Global Trade Review 2023).

The Role of SAE Standards in Headlight Design and Performance Evaluation

The Society of Automotive Engineers, commonly known as SAE, has developed some voluntary standards over the years. For instance, their J1383 standard covers photometric testing requirements, while J583 deals specifically with fog light dispersion characteristics. Most car makers in America actually follow these recommendations already - around 89 percent according to industry reports. These guidelines help push forward new technologies like LED matrix headlights at the same time they make sure everything still complies with the Federal Motor Vehicle Safety Standards number 108. Last year saw an important update too. The 2022 revision of SAE J3069 brought in specific testing procedures for lights on self driving cars. Not surprisingly, this work ended up influencing the National Highway Traffic Safety Administration when they were drafting their own rules about autonomous vehicle illumination systems recently.

How Quality Car Lamp Assemblies Enhance Road Safety and Driver Performance

How Certified Automotive Lighting Enhances Nighttime Visibility and Driver Reaction Time

Car lamps that meet DOT and ECE standards can boost night vision by around 40% when compared to those that don't pass these tests, as found by the Insurance Institute for Highway Safety. When low beams are correctly aligned and equipped with anti-glare features, drivers spot people walking on the road about 2.3 seconds earlier at speeds of 60 miles per hour. That extra time matters a lot when trying to avoid accidents. Newer tech such as high beam assistance works smartly behind the scenes. These systems automatically change how bright the lights are depending on how fast the car is going and where it's turning, making roads safer without breaking any of the FMVSS 108 rules about light distribution.

Statistics on Accidents Linked to Non-Compliant or Poorly Aligned Headlight Assemblies

The IIHS estimates 51% of fatal crashes occur in low-light conditions, with vehicles using substandard headlights 2.6 times more likely to be involved in nighttime collisions. A 2023 NHTSA analysis found 18% of inspected vehicles had misaligned headlights exceeding 0.5° vertical deviation—sufficient to blind oncoming drivers at 150 feet.

NHTSA and DOT Enforcement of Automotive Lighting Standards

NHTSA recalled 127,000 vehicles in 2023 due to non-compliant lighting, mandating free repairs under 49 CFR §571.108. Federal regulators conduct factory audits to verify photometric data, with manufacturers facing fines up to $22,992 per violation for falsified certification labels.

LED Headlight Compliance: Balancing Innovation with Legal and Safety Requirements

Regulatory Hurdles for LED Headlight Certification and Aftermarket Modifications

LED headlights these days have to go through really strict testing according to both DOT and ECE standards. They need just right beam shapes, proper glare management, and must withstand heat without failing. Getting approval can take anywhere from 12 to 18 months sometimes, which is pretty long when compared to older tech. The aftermarket modifications create even bigger headaches though. When people try putting LED bulbs into regular halogen light housings, they often end up breaking federal rules. According to research, around two thirds of these DIY installs don't pass simple checks for alignment issues or excessive glare problems. That's not just bad for passing inspections either it actually puts drivers at risk on the road.

Common Violations in LED Headlight Assemblies: Glare, Beam Pattern, and Alignment

The biggest problem people run into with vehicle lighting? Glare caused by bad optics or when things aren't aligned properly. When old halogen reflectors get swapped out for LED bulbs, they tend to throw light all over the place instead of focusing it where it should go, which makes driving dangerous at night. These kinds of beam pattern problems - think about those cutoff lines not working right or hotspots appearing where they shouldn't - are responsible for about 41 percent of all DOT compliance issues according to recent data. The National Highway Traffic Safety Administration definitely takes this seriously because if headlights aren't lined up correctly, drivers lose precious reaction time when visibility drops. We're talking around 1.2 seconds lost during emergencies on dark roads, which sounds short but can make all the difference between stopping safely and something worse happening.

Controversy Analysis: OEM vs. Aftermarket LED Upgrades and Regulatory Loopholes

Original equipment manufacturer LED systems come with built-in optical components and factory calibrated settings that meet FMVSS 108 and ECE R48 requirements right out of the box. Aftermarket lighting solutions frequently work around regulations by claiming things like "for off-road use only" so they don't have to go through proper safety tests. According to Ponemon Institute research from last year, this regulatory gap has led to about 740 million dollars worth of questionable products circulating in the market. Twenty nine states currently ban vehicle retrofits, but enforcement varies widely across regions. As a result, roughly one in five cars with upgraded lighting actually runs on lights that fall below minimum safety standards. Government officials are pushing for standardized international guidelines that would plug these legal gaps while still allowing room for new technologies to develop naturally over time.

Engineering and Optical Design of Car Lamp Assemblies for Glare Control and Safety

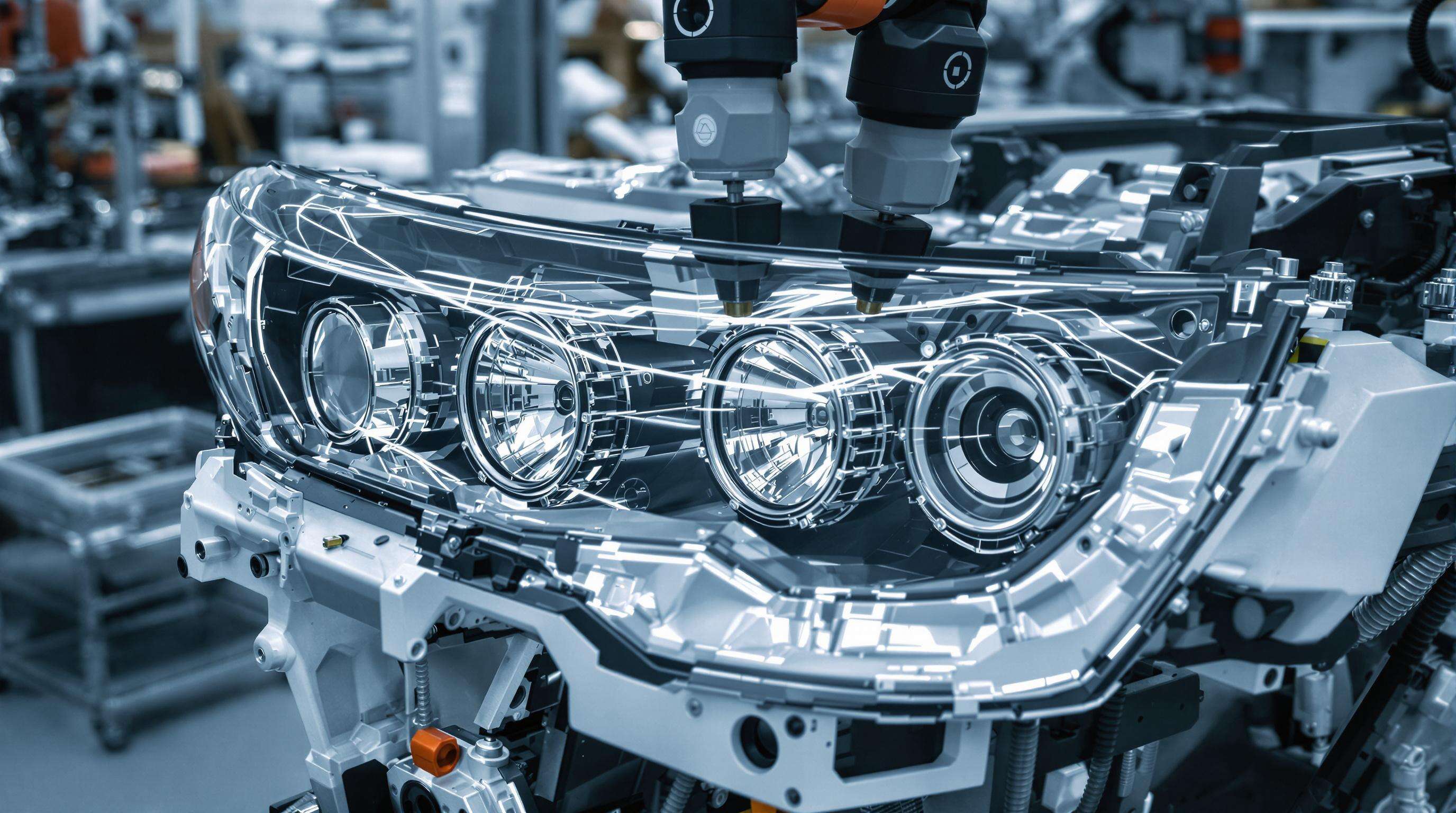

Car headlight systems today need really careful optical design to balance between controlling glare for other drivers and still providing good road visibility. The reflector shapes, lens materials, and how light gets spread across the road all have to work together pretty well. Most modern headlights manage to get around 90 to 95 percent of their total light output focused where regulations say it should be, following standards set by groups like ECE R112 and SAE J1383. To hit these tight specs, car makers now rely on robots that align everything down to fractions of a degree. These machines keep angles spot on within plus or minus 0.3 degrees, which stops those annoying bright spots from forming that would go over the 300 cd per square meter limit introduced in last year's safety revisions. Getting this right matters a lot for both driver comfort and road safety.

Importance of Proper Headlight Assembly Design and Beam Control

Getting rid of unwanted glare depends heavily on reflector bowls that are shaped just right and lenses with tiny structures that direct light exactly where it needs to go. When manufacturers cut corners on design, we end up with light scattering at levels over 500 cd per square meter according to research from the Insurance Institute for Highway Safety. These high levels actually slow down drivers reacting to oncoming traffic by about three quarters of a second. Modern materials made from special plastics keep their shape within 0.05 millimeters even when temperatures swing between minus 40 degrees Celsius and 120 degrees Celsius. This kind of stability makes it possible to manufacture large quantities of optical components without losing precision in how they distribute light beams across different conditions.

Headlight Beam Patterns and Alignment in Relation to Oncoming Driver Safety

Regulated asymmetric low-beam patterns feature a 1.5° upward gradient for sign visibility and a sharp 0.57° horizontal cutoff to protect opposing traffic. NHTSA data shows properly aligned systems reduce glare-related collision risks by 38%. Adaptive leveling systems using MEMS gyroscopes compensate for vehicle pitch within 150 ms—faster than human glare response thresholds.

Advanced Optics and Adaptive Lighting Technologies Meeting ECE and DOT Requirements

Matrix LED systems with 1,024 individually controllable segments dynamically reshape beams around detected vehicles, maintaining 80 lx roadway illumination while reducing glare exposure by 73% (DOT 2023 testing). Micro-optical light guides with 5μm tolerance Fresnel structures now enable single-light solutions that meet both ECE asymmetrical and DOT symmetrical photometric requirements without mechanical adjusters.

Testing, Certification, and Verification of Car Lamp Assemblies for Regulatory Compliance

Compliance Testing for Car Lamp Assemblies: Vibration, Waterproofing, and Thermal Stress

Car lamp assemblies undergo rigorous validation to meet global standards. Third-party labs simulate long-term wear through:

- Vibration testing replicating 150,000+ miles of road stress

- IP67 waterproofing validation via high-pressure water jets

- Thermal cycling between -40°C and 85°C to prevent lens cracking

A 2023 FMVSS No. 108 amendment introduced new photometric thresholds, requiring 15% wider beam patterns for improved pedestrian detection in low-light conditions.

Laboratory vs. Real-World Validation of Headlight Performance

While lab tests confirm theoretical compliance, real-world conditions reveal performance gaps. SAE research shows LED assemblies passing lab audits underperform by 23% in rain and fog due to environmental scattering:

| Test Condition | Laboratory Validation | Real-World Performance |

|---|---|---|

| Heavy Rain | 85% light retention | 62% light retention |

| Mixed Fog | 78% beam clarity | 54% beam clarity |

Third-Party Certification Bodies and Their Role in Ensuring DOT and ECE Compliance

Independent auditors like TÜV SÜD and Intertek evaluate 87 compliance parameters, from glare angles to voltage stability. Their 2024 benchmark found only 42% of aftermarket LED kits met both ECE R112 and FMVSS 108 requirements, highlighting the complexity of multinational certification.

FAQ

What are the main differences between FMVSS 108 and ECE regulations for headlights?

FMVSS 108 focuses on fixed vertical alignment and a brightness limit of 1,200 cd/m² for low beams, while ECE regulations require dynamic leveling and have a total output limit of 75,000 cd for brightness.

Why is DOT certification important for car headlights?

DOT certification ensures that car headlights meet safety standards set by the FMVSS 108, which is crucial for preventing accidents and ensuring proper light distribution on roads.

What are the challenges faced by LED headlight compliance?

LED headlights must meet rigorous DOT and ECE standards, including beam shape, glare management, and heat resistance. Aftermarket modifications often face challenges with alignment and excessive glare, making compliance difficult.

How do adaptive lighting technologies enhance safety?

Adaptive lighting technologies, such as matrix LED systems, dynamically adjust beam patterns to reduce glare while maintaining optimal road illumination, thus enhancing safety for both the driver and oncoming traffic.