Precision Mold Engineering in OEM-Grade Replacement Parts

The Role of Precision Mold Engineering in OEM-Grade Replacement Parts

Why Mold Accuracy Matters in Auto Body Parts Manufacturing

Getting mold engineering right matters a lot for making auto body parts, particularly when those parts need to fit together just right. When molds aren't accurate enough, we end up with parts that don't fit properly. This causes extra expenses and really hurts customer satisfaction too. The numbers back this up industry wide - lots of returned parts because they simply don't work as intended, which hits both suppliers and car makers where it hurts most. What's more, bad mold work can actually impact vehicle safety something regulators like NHTSA take very seriously indeed. Following their safety standards means ensuring all those components actually work as designed without compromising any safety features built into modern cars. That's why getting mold engineering right isn't just about looks or function it's fundamental to producing quality auto body parts that meet today's tough safety and fitment demands across the board.

Meeting Automotive Industry Standards Through Advanced Tooling

The automotive industry has strict rules about quality control, particularly when following standards like ISO/TS 16949. Precision mold engineers rely on cutting edge tooling methods to hit those quality targets consistently across production runs. These regulations basically force manufacturers to produce parts that match exact measurements every single time they come off the line. Modern shops now incorporate things like CNC machines and EDM technology which make it possible to craft intricate molds that would otherwise be impossible to create manually. Getting certified isn't just about ticking boxes on paperwork either. Businesses that actually follow these guidelines tend to stand out from competitors because customers know they're getting reliable products. Take auto body parts for instance - people want components that fit perfectly without warping or breaking after installation. That's why so many successful companies invest heavily in upgrading their tooling capabilities. It builds credibility in the marketplace while also making sure operations run smoothly under constant scrutiny from regulatory bodies.

CNC Machining for Complex Auto Components

CNC machining is really important when it comes to making those detailed, complicated designs needed for OEM quality molds, especially when producing car body components. The whole process is controlled by computers, which lets machines move and operate with incredible precision so manufacturers can actually make these complex shapes accurately. What makes CNC so valuable? Well, it cuts down on both time and money because of all the automated functions built into the system. According to industry reports, factories using CNC tech see around a 20 percent boost in productivity overall. This means auto makers get their body parts produced faster while maintaining that high level of quality we expect from original equipment manufacturer standards.

EDM Applications in Precision Collision Parts

EDM plays a critical role in creating those exacting shapes and complex details needed in mold making, particularly when working on automotive components such as bumpers and frames. Real world applications demonstrate that EDM not only improves overall mold quality but also cuts down on wasted material, something manufacturers struggle with constantly in collision part fabrication. When used alongside traditional CNC machining methods, EDM allows shops to hit those tight tolerances required by the industry. This combination ensures finished products pass all the necessary crash tests while still maintaining structural integrity under real road conditions.

Moldflow Simulation for Optimal Material Distribution

Moldflow simulation tech plays a big role in figuring out how materials move around inside molds when things get made. When manufacturers run these simulations, they spot problems before they happen, especially those pesky issues caused by materials not spreading evenly throughout the mold. That means better quality auto parts coming off the line. Shops that have adopted Moldflow simulations tell us they see real differences in their quality checks. Fewer mistakes show up on the factory floor, and production runs go smoother overall. For car makers who need to hit strict quality targets, this kind of predictive tool isn't just helpful it's pretty much essential nowadays.

Applications in Auto Body Replacement Parts Production

Ensuring Fitment Accuracy for Online Auto Parts Retail

Online auto parts shopping has made fitment accuracy a major concern for keeping customers happy. People just want parts that actually work with their cars when they order them from websites. When something doesn't fit right, it causes frustration and lots of returns. Many retailers now use special software programs that match parts with exact vehicle models. These tools let shoppers check if a part will fit before buying. Some industry reports show that getting fitment right cuts down return rates around 40 percent. Better fitment means happier customers who leave good reviews and come back again later.

Material Selection Strategies for Durable Aftermarket Components

Picking suitable materials when buying aftermarket auto body parts makes all the difference in how long they last and whether they work properly. Materials vary quite a bit these days, with options ranging from thermoplastic resins to various metal alloys, each better suited for different types of components. Take thermoplastics for example they tend to hold up pretty well against corrosion and wear down slower than many alternatives. Metals on the other hand bring their own strengths to the table, offering superior structural integrity where needed most. Most industry folks will tell anyone who asks that getting the material choice right really affects how well the part performs down the road. High quality materials generally make parts last somewhere around 30 to 50 percent longer before needing replacement, which means customers end up saving money and hassle in the long run.

OEM-Grade Replacement Parts Showcase

SK FABIA 07-14 Rear Bumper Bracket: OEM Compatibility & Durability

What makes the SK FABIA 07-14 rear bumper bracket really special is how well it fits vehicles from 2007 to 2014 models. Made from black polypropylene material, this part matches factory specs down to the millimeter for proper collision repairs. The PP construction holds up surprisingly well against road debris and weather conditions over time. Many mechanics report that installing these brackets takes less time compared to other brands, and customers often mention how much better their cars look after replacement. Those interested should look up SK FABIA 07-14 parts listings for full specifications and availability information.

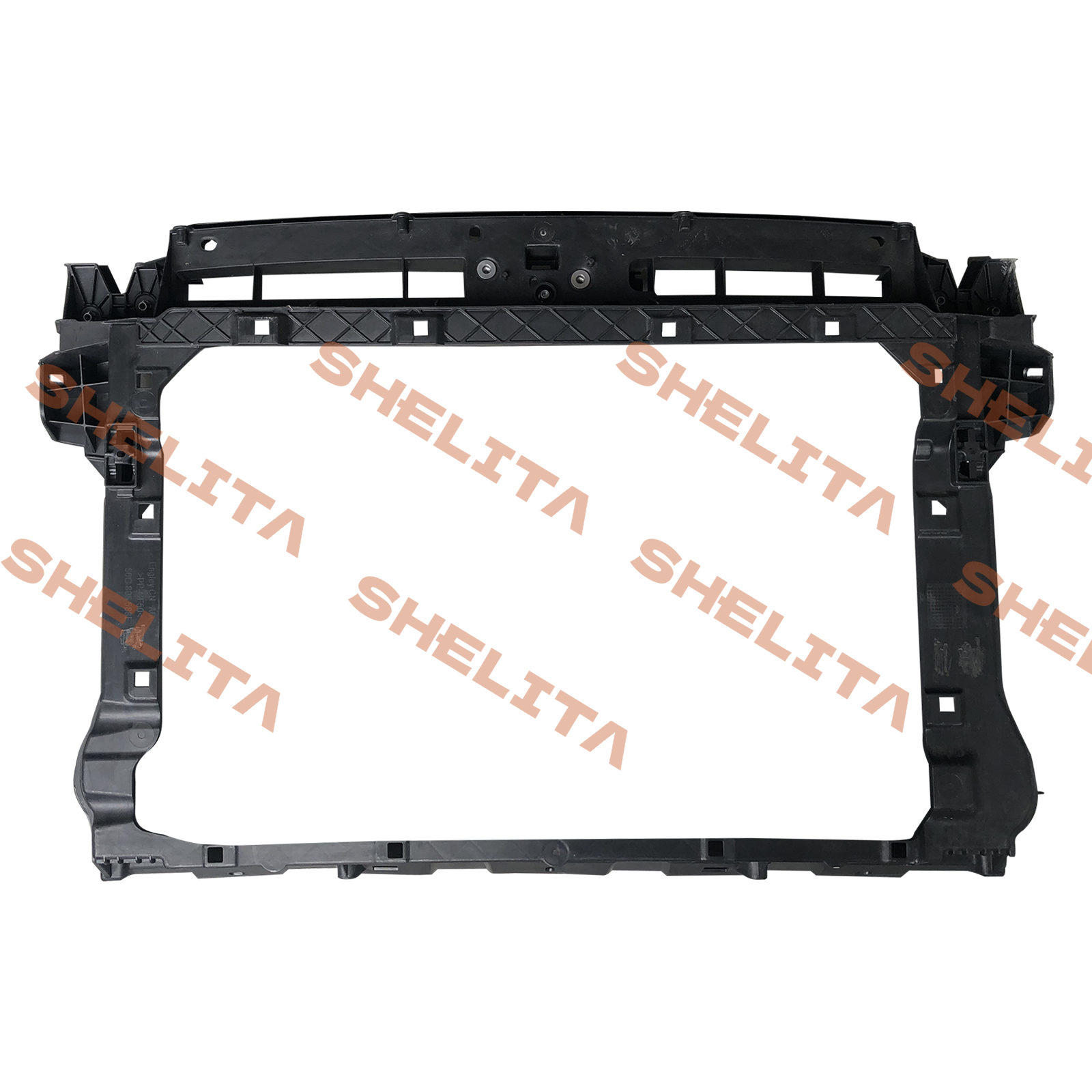

SK KAROQ 17- Radiator Support System: Precision Engineering for Modern Vehicles

The SK KAROQ 17 radiator support system shows what good engineering looks like, and works great in today's cars. Made from solid plastic materials, it fits right into modern vehicle designs and matches up well with both 1.0TSI and 1.5TSI engines without any issues. Mechanics who install these parts often notice better stability when driving, plus the cooling system just runs smoother overall. Real owners report their cars handle better on the road too, with no overheating problems during long drives. Want to learn more details about how this component performs? Just search for SK KAROQ 17 online.

TA CAMRY 18- Washer Tank Assembly: Integrated Fluid Management Solutions

Take a look at the TA CAMRY 18 washer tank assembly - it really stands out when it comes to how fluids are managed within cars. What makes this setup so good? Well, it comes with everything needed right from the start: there's the main tank itself plus all those little parts like pipes, caps, and even a motor included. This kind of attention to detail means drivers get proper fluid handling without any extra hassle. Manufacturers put quite a bit into making sure these components work together flawlessly, which explains why mechanics often praise them after installation. People who've used this system report great results too, especially during harsh weather where clear visibility matters most on the road. Want to know exactly what goes into building such reliable equipment? Check out TA CAMRY 18 for full specs and technical information.

Quality Assurance in Auto Body Parts Supply Chain

Certification Processes for Online Auto Parts Suppliers

Getting certified is pretty much a must for anyone selling auto parts online who wants to make sure their stuff meets safety and quality standards. Most serious suppliers go through the process of getting important certifications like ISO and IATF. These aren't just paper certificates sitting on a shelf either. The ISO 9001 certification basically means a company follows quality management practices that everyone around the world recognizes. Then there's IATF 16949 specifically for auto parts suppliers, making sure they hit those tough industry quality marks. Some stats from the International Organization for Standardization show that companies sticking to these standards tend to get preferred by customers about 80% more often. Beyond just checking boxes for regulations, these certifications actually help businesses stand out in what's become a really competitive market for online auto parts sales.

Traceability Systems in Collision Repair Components

Traceability systems are really important when it comes to keeping collision repair parts reliable and safe. When shops use things like RFID tags, they can track where every component goes from factory floor all the way to customer hands. For instance, many suppliers now scan parts at multiple points during shipping, which helps them spot problems early on before bad or fake parts ever reach mechanics' toolboxes. The NHTSA actually did some research showing cars with good tracking systems had about 30% fewer recall issues than those without proper documentation. Makes sense why insurance companies care so much about this stuff too. After all, nobody wants to install something that might fail later down the road just because no one knew where it came from originally.