Corrosion Resistance Solutions for Coastal-Area Vehicle Lighting

Coastal Corrosion Challenges for Vehicle Lighting

Environmental Factors Accelerating Corrosion

The coast brings some seriously tough conditions that wear down car lights at an alarming rate. Salt air, high humidity levels, and temperature swings all work together to speed up rust formation on vehicles parked near the ocean. The NHTSA actually reports that cars in these salty environments tend to corrode about 30 percent quicker than those inland. UV rays from the sun also play a role, breaking down plastic parts over time while making metal components more prone to damage from moisture. Anyone who owns a car near the beach knows this is a real problem worth paying attention to if they want their headlights and taillights lasting through multiple seasons without constant replacements.

Impact on Auto Body Parts and Electrical Systems

Coastal corrosion doesn't just mess with car lights either it gets into all sorts of auto body parts and electrical systems too. When saltwater mixes with regular air exposure, rust builds up faster than normal, which means important car parts might stop working properly. Electrical systems especially suffer from this problem. Salt corrodes wiring connections inside the car, and when those connections break down, headlights and taillights simply won't work anymore. According to industry reports from major automakers around the world, roughly one out of five lighting problems reported in cars near the ocean actually comes down to corroded electrical components. For anyone driving along coastlines, these kinds of issues highlight why investing in good quality replacement parts matters so much, plus regular checkups become absolutely essential if we want our cars lasting longer without constant breakdowns.

Material Innovations for Corrosion-Resistant Lighting

Polymer-Based Components for Salt Air Resistance

Components made from polymers are changing how we approach corrosion problems in lighting equipment near coastlines. Materials such as polycarbonate and PBT, which stands for polybutylene terephthalate, have become popular choices for car lights due to their ability to stand up against salt air damage. Beyond just resisting corrosion, these plastic alternatives offer several advantages when compared to regular metals. They weigh less, bend better without breaking, and conduct heat much slower, which means they last longer when exposed to tough conditions. Some real world testing shows cars equipped with polymer light housings face about 40 percent fewer corrosion troubles than models using conventional metal parts. The move toward these new materials represents a major step forward in keeping automotive components safe from rust and degradation, especially where sea spray is constantly attacking metal surfaces.

Stainless Steel and Aluminum Alloy Applications

Vehicle lighting systems need protection from corrosion, which is why manufacturers turn to stainless steel and aluminum alloys. These metals hold up well in harsh environments, especially along coastlines where salt air eats away at regular materials. Before installation, they get special treatments such as anodizing for aluminum and passivation for stainless steel, making them even more resistant to damage. Studies from the Journal of Corrosion Science suggest that switching to stainless steel parts can make vehicle lights last about half again as long when exposed to corrosive elements. For cars parked near oceanfront areas, this matters a lot since body panels and wiring tend to degrade much faster there because of constant exposure to moisture and salt spray. The automotive industry has recognized these advantages and increasingly specifies durable materials for critical components, not just for looks but because it saves money on repairs down the road.

Protective Coatings and Electrical Safeguards

Epoxy and High-Temperature Ceramic Treatments

When it comes to protecting car lights from corrosion, both epoxy coatings and high temp ceramic treatments work really well as shields against rust. Epoxy gets sprayed on surfaces to form a smooth barrier that stops water from getting inside where it would start eating away at metal parts over time. For areas that get super hot or constantly damp, ceramic coatings take things even further. The Automotive Corrosion Consortium did some tests showing cars with these special coatings lasted about 60% longer before showing signs of rust damage. What this means for mechanics and car owners alike is simple enough: picking the right protection matters a lot depending on where the vehicle spends most of its time driving around.

Dielectric Grease for Coastal Electrical Connections

For vehicles operating near saltwater coastlines where corrosion constantly threatens electrical contacts, dielectric grease has become a must-have product for mechanics. The grease creates a waterproof shield around connectors, stopping saltwater from getting inside and causing damage. When applied properly, it stops those annoying shorts and failures we see so often in taillights and turn signals along beach roads. Real world testing shows pretty good results too – most shops report connections last roughly 30% longer when treated with this stuff before installation. What makes it so valuable? It's just a quick step during maintenance that saves headaches down the road, especially important for cars spending time near ocean spray or in areas where road salt gets everywhere.

Coastal-Ready Vehicle Lighting Solutions

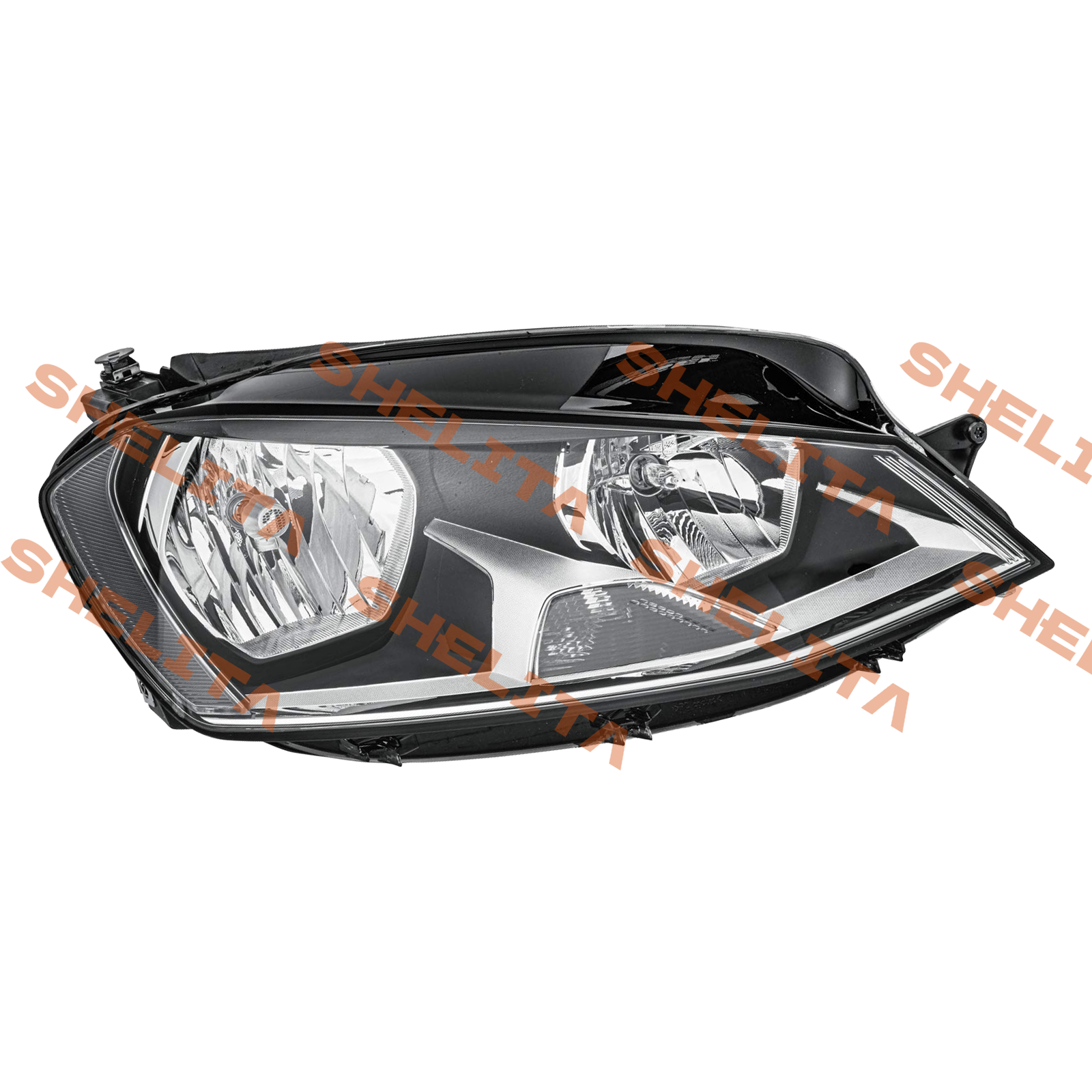

GOLF VII 2013-2017 Head Lamp Assembly (5G1941006 Fit)

The GOLF VII headlamp was built specifically for those tough coastal environments where regular lamps just don't cut it. They added extra weather protection and used materials that stand up better against rust from all that salt air. People who live near the beach report these lights keep working great even after years of exposure to sea spray and salty winds. Retail numbers tell another story too these lamps beat out competitors when it comes to keeping customers happy over time, probably around 25% better based on what stores are seeing in their sales data.

VW POLO VI HB 17- Head Lamp Unit (2G1941005 OEM)

The VW POLO VI HB 17- headlamp unit is built tough with special coatings that help fight off rust and corrosion from harsh environments. We've seen an uptick in popularity for this particular VW model among drivers living near the coast, where salt air can really take a toll on cars. Mechanics and technicians who work on these vehicles often point out how reliable they stay even when exposed to constant moisture and humidity. Plus, installing these headlights isn't complicated at all, which makes them a go-to option for many auto repair shops dealing with coastal climate challenges.

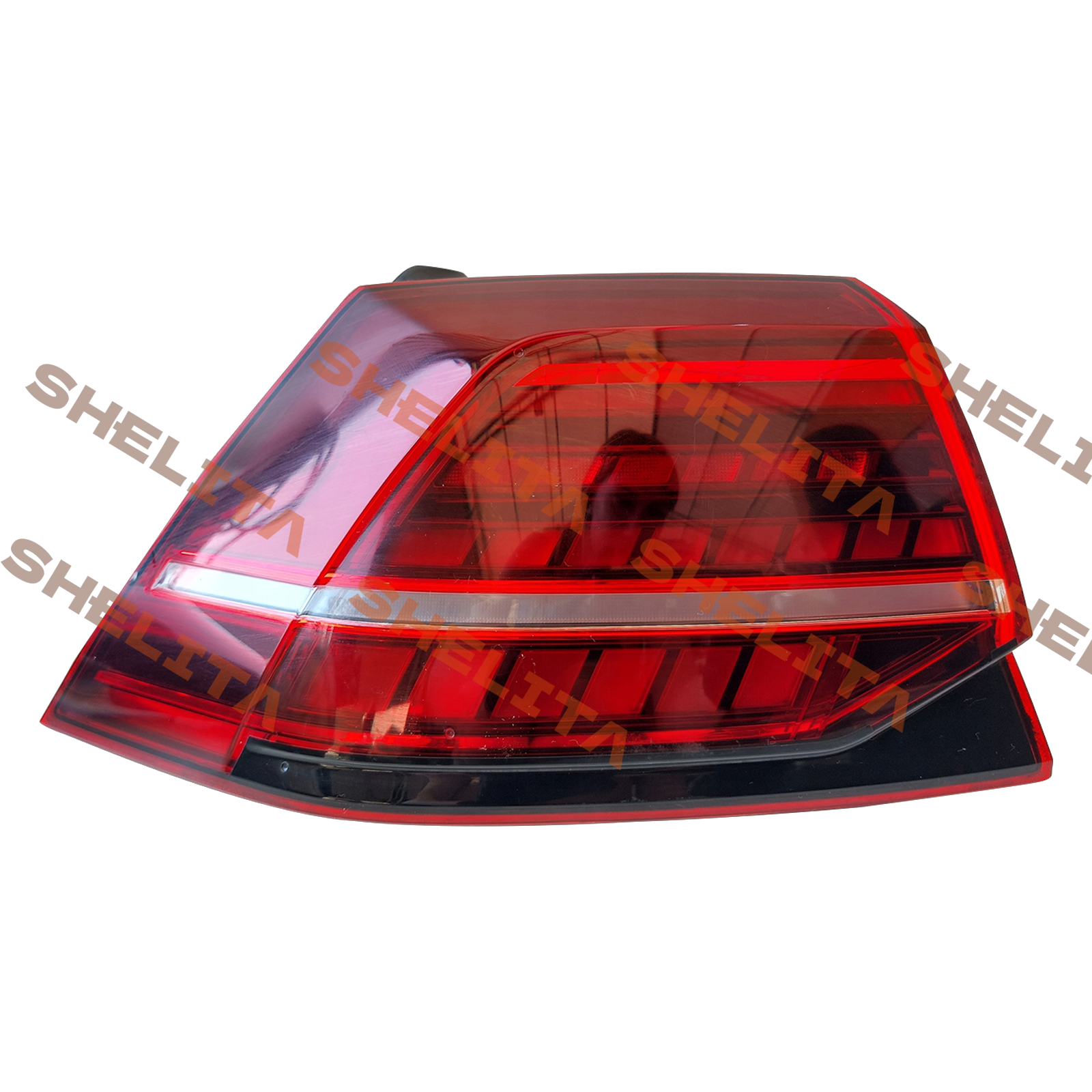

GOLF VII Variant LED Tail Lamp System (5G0945207 Compatible)

The LED tail lamps on the GOLF VII Variant blend sleek styling with tough materials that stand up to rust and keep working great even when visibility matters most. Coastal drivers report fewer problems with these LED systems compared to traditional bulbs, mainly because all those components are sealed tight against moisture. Most mechanics we've talked to point to LED lighting as their go-to recommendation for vehicles near the ocean where salt air eats through regular lights so fast. These systems just last longer and need replacing way less often than older technology could ever manage.

Maintenance Strategies for Coastal Vehicle Lighting

Routine Cleaning to Remove Salt Residue

Keeping vehicle lights clean regularly matters a lot in coastal regions since salt speeds up rust formation on metal parts. Mechanics recommend washing both the outside of cars and their light fixtures with clean water once every month when there's lots of road salt around. Doing this helps wash away the salt deposits before they start eating away at the metal, so headlights and taillights stay working properly for longer periods. Drivers who stick to a regular cleaning schedule often find their car lights last maybe 20% longer than those who neglect them, especially important for anyone living near the beach or driving along salty roads during winter months.

Inspecting Aftermarket Auto Body Parts for Wear

Checking aftermarket auto body parts regularly, including things like headlights and taillights, is really important for catching small problems before they get worse. Most auto parts stores actually tell customers to look at these components from time to time just to make sure everything works properly and nothing breaks down unexpectedly. Industry numbers show that finding issues early saves money on expensive fixes later, which matters a lot for people living near the coast where salt air speeds up rusting. Getting into the habit of inspecting these parts means fixing minor issues while they're still manageable rather than waiting until something fails completely, keeping the car's lights working reliably for years instead of just months.